Optimal automation

Working together with specialist suppliers to achieve an optimal process result for the customer.

Just before the holidays, Lentink received a new order from one of its customers for the production of special large heating devices. These specials consist of about 20 different large standing models that are now randomly produced by Lentink. Great accuracy, planning, quality and process repeatability are required, as with most products that Lentink produces.

Immediately after the holiday in mid-September, we once again received a new large project for the same customer. The numbers per year are such that Lentink will have to have the production of the products fully automated.

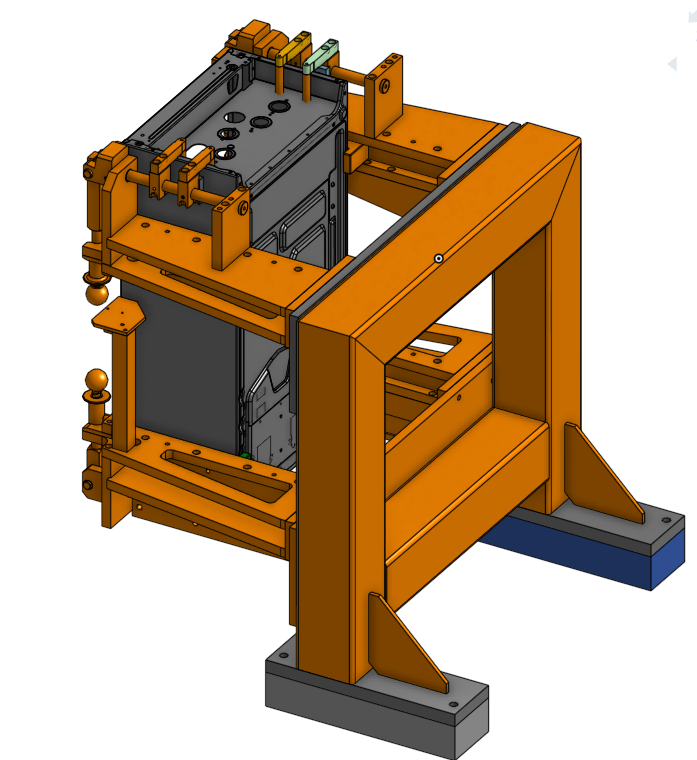

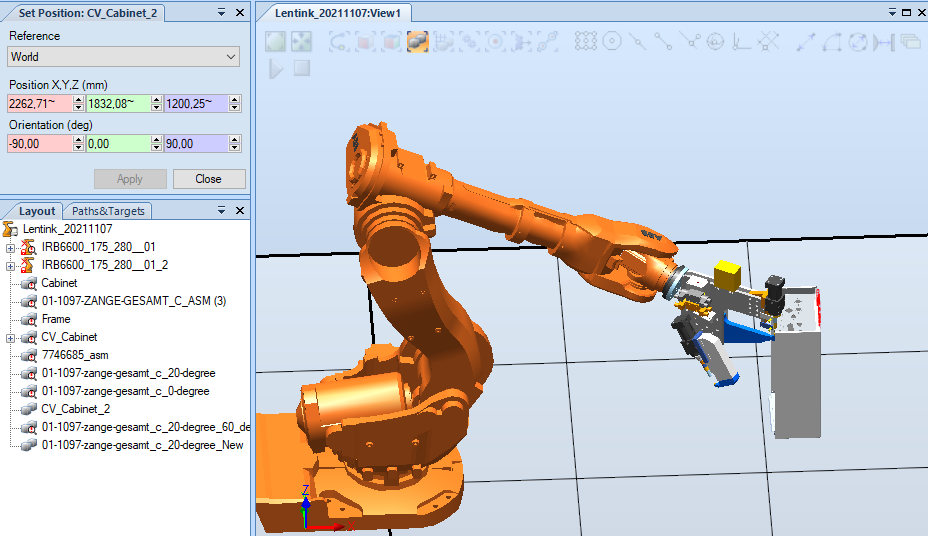

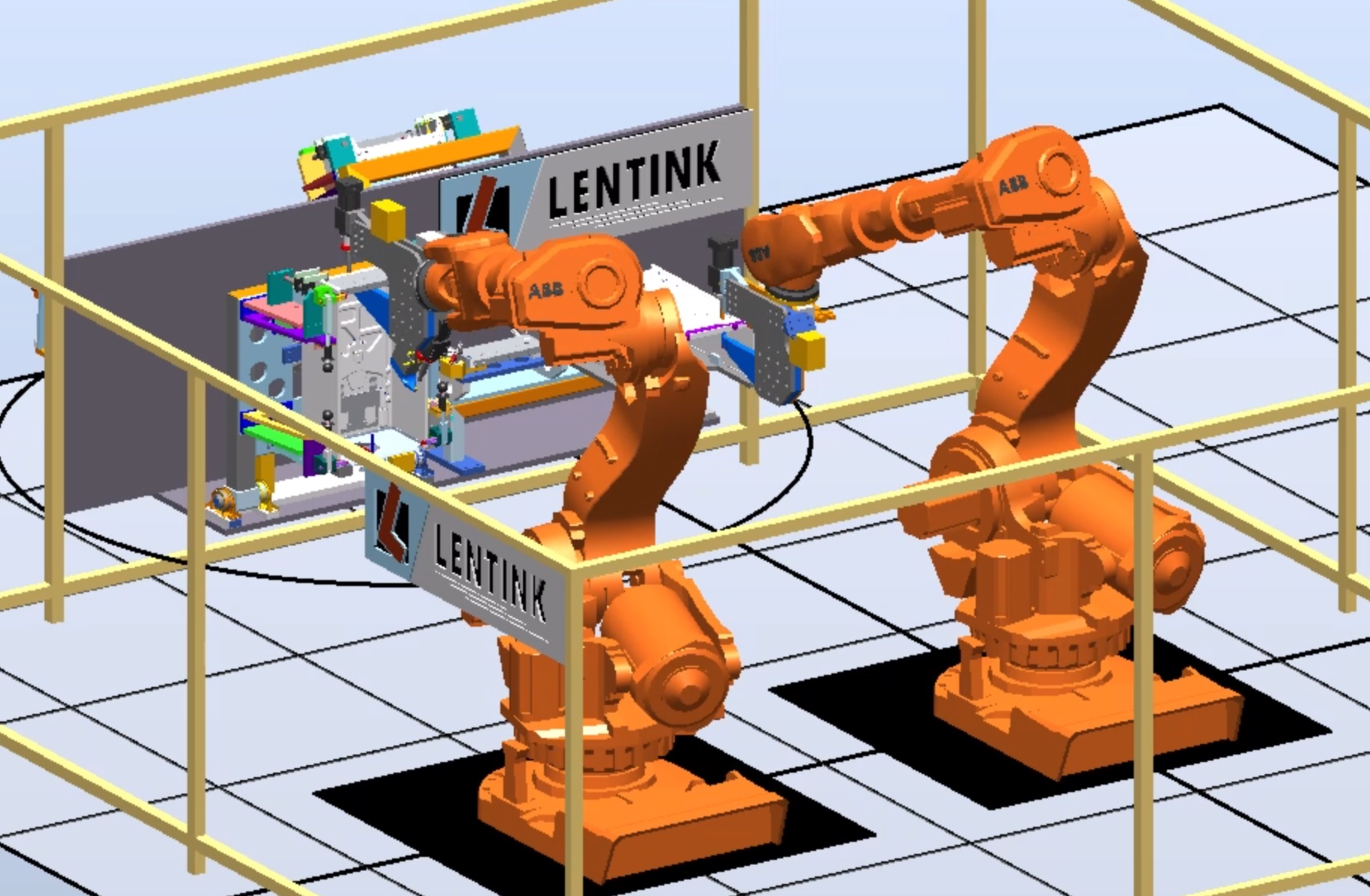

The automatic process will partly take place under one or more Lentink presses and the other operations such as assembly, mounting and powder coating will be carried out as efficiently as possible within the known standard processes. Putting together, assembling, we try to explain below.

Due to strongly increasing global competition, process innovation also deserves the full attention of the sheet metal processing industry. In order to keep our competitive position in Europe at a minimum level and if possible even strengthen it, we try to improve our added value in new projects through technological process innovation, the effective use of capital-intensive production resources, as well as by reducing our wage share in the production process. . Our employee must be deployed as efficiently as possible within production hours. This means that the operator must be deployed on activities in the production process that cannot or can hardly be automated. These activities should preferably be standardized as much as possible. The clamping means must optimally match the machining capabilities of the robot machine and the repeatability of the clamping means, so that a reliable process is realized. Employees can use their time optimally through standardization. This also shortens the lead time of the entire machining process and increases reliability and quality. The employee can therefore perform other operations while the robot(s) are performing their operations. Due to our automation and standardization, relatively fewer actions are performed by the employee. So effectively fewer man-hours are put into the total product, which reduces the wage component in the product and therefore the cost price of the product. Fewer man-hours is therefore one of the preconditions for being able to face competition in Europe to some extent.

Lead time and 'time to market' of the product is important for Lentink's customers. Most Lentink's customers do not want stocks and only want to receive the products and then assemble them on their production lines that have already been sold (built to order). For Lentink, this means that the customer calls up fluctuating batch sizes and irregular product orders. Because the products we produce for the customers have already been sold, it must be possible to deliver them quickly.

Automating production within Lentink certainly means that this is at the expense of jobs. Due to the productivity, short lead time and repetitive quality, Lentink's competitive position is kept at a somewhat comparable level, as indicated earlier. It is therefore demonstrable within the Lentink production that employment has been preserved through automation. If applicable, Lentink also offers automation the solution to the shortage of specialized personnel. With an automated process, there is still some competition in the Netherlands with low(re)wage countries. The cost price in a low-wage country must of course be increased by the higher transport costs and storage costs.

Specialist suppliers are currently working on the robot automation that should be operational within Lentink by mid-February/March 2022. Collaboration is an important part of this in order to be able to succeed, within the shortest possible lead time, in order to be operational at the beginning of this year. Preparation by performing simulation tests, for example, is essential in this regard.

Made possible by and for our customers. We thank our customer again for the orders and the trust. You ask Lentink, with Lentink you succeed.